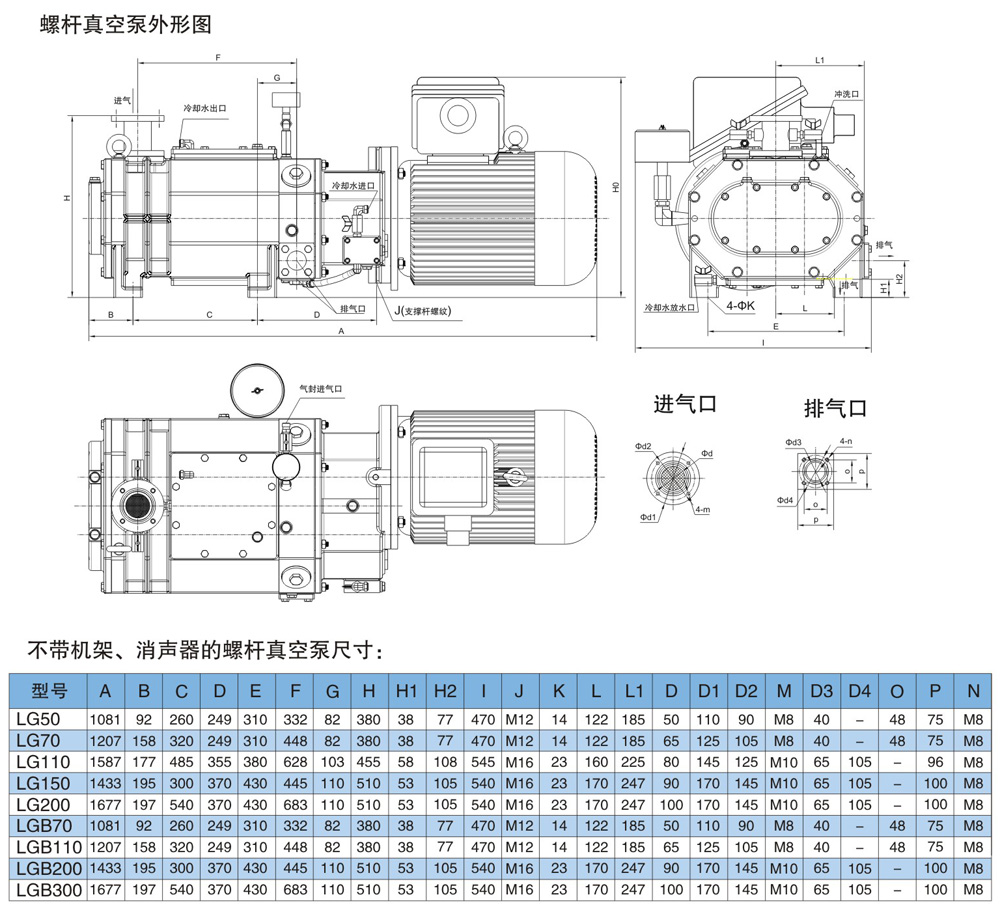

LG/LGH screw vacuum pump series

Screw vacuum pump is a studio consisting of a pair of parallel helical rotor and pump body, no friction between the rotor and the pump body and keep a certain gap in the seal cavity is formed between the two rotor and pump body, when the rotor rotates the gas seal cavity continuously to squeeze the air outlet. Because of the need of lubricating oil or water seal screw vacuum pump, the pump chamber completely without oil, so oil free dry screw vacuum pump is a vacuum pump, no oil clean occasions, chemical and pharmaceutical of solvent recovery process in semiconductor and electronic industry has the incomparable superiority, can effectively substitute. Vane vacuum pump, vacuum pump.

A lead screw vacuum pump is the equivalent of a screw pump, vacuum pump multiple lead equivalent multistage pump series, compared with the claw type dry vacuum pump vacuum pump, roots vacuum pump multi-stage series, because there is no internal passage between levels of pump screw vacuum pump, which is directly to the gas from the suction side to push the exhaust side, so the pumping condensable gas, with gas and dust particles when no blockage and easy cleaning.

The company's production of screw pump has the following characteristics:

1, high vacuum degree, single pump pressure limit of LG = 1Pa, LGH = 5Pa, high vacuum pumping capacity.

2, high efficiency, low power consumption.

3. No oil in the pump cavity, no pollution to the pumping system.

LG series 4 screw pump rotor clearance is relatively small, the ultimate vacuum degree is higher, which is suitable for semiconductor and electronic industry in the workplace clean without oil; LGH series screw pump rotor gap is relatively large, limit vacuum degree is relatively low, the pump cavity and the rotor surface plating layer or PTFE coatings are available, can pumping a large amount of water vapor and corrosive medium, suitable for work in chemical, pharmaceutical and other working environment is bad.

5, no waste oil, wastewater discharge, no pollution to the environment.

6, the structure is simple, compact, easy maintenance, small footprint.

Screw vacuum pump is a studio consisting of a pair of parallel helical rotor and pump body, no friction between the rotor and the pump body and keep a certain gap in the seal cavity is formed between the two rotor and pump body, when the rotor rotates the gas seal cavity continuously to squeeze the air outlet. Because of the need of lubricating oil or water seal screw vacuum pump, the pump chamber completely without oil, so oil free dry screw vacuum pump is a vacuum pump, no oil clean occasions, chemical and pharmaceutical of solvent recovery process in semiconductor and electronic industry has the incomparable superiority, can effectively substitute. Vane vacuum pump, vacuum pump.

A lead screw vacuum pump is the equivalent of a screw pump, vacuum pump multiple lead equivalent multistage pump series, compared with the claw type dry vacuum pump vacuum pump, roots vacuum pump multi-stage series, because there is no internal passage between levels of pump screw vacuum pump, which is directly to the gas from the suction side to push the exhaust side, so the pumping condensable gas, with gas and dust particles when no blockage and easy cleaning.

The company's production of screw pump has the following characteristics:

1, high vacuum degree, single pump pressure limit of LG = 1Pa, LGH = 5Pa, high vacuum pumping capacity.

2, high efficiency, low power consumption.

3. No oil in the pump cavity, no pollution to the pumping system.

LG series 4 screw pump rotor clearance is relatively small, the ultimate vacuum degree is higher, which is suitable for semiconductor and electronic industry in the workplace clean without oil; LGH series screw pump rotor gap is relatively large, limit vacuum degree is relatively low, the pump cavity and the rotor surface plating layer or PTFE coatings are available, can pumping a large amount of water vapor and corrosive medium, suitable for work in chemical, pharmaceutical and other working environment is bad.

5, no waste oil, wastewater discharge, no pollution to the environment.

6, the structure is simple, compact, easy maintenance, small footprint.