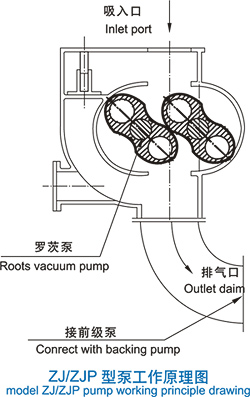

Magnetic force transmission is adopted for the pump gearing between motor and pump that is first time in our country.

Characteristic:

● Magnetic force transmission transfer moment, the dynamic seal of the main shaft that transfer twist moment is calm seal (no framework oil seal and mechanical seal), it is achieved that there is no leak when the dynamical is being transferred.

● No machine contacting and Rubbing noise, avoid the high frequency vibration when dynamical is being transferred, stable operation.

● Possess overload self-protective function.

● No impact when start compare to Rigid coupling, Install \ dismantle to unload, test and maintain expediently.

● Sheath for insulation and Calm seal replaced moving seal. Vacuum and lubricant leak is avoided completely because of abrasion of the shaft moving seal.

● Do not need lubricate, no medium and lubricant pollutions, Purify the environment

The Sealing performance is foreign to the shaft speed.

Installation dimension and performance of the series pump is the same with the general roots pump.

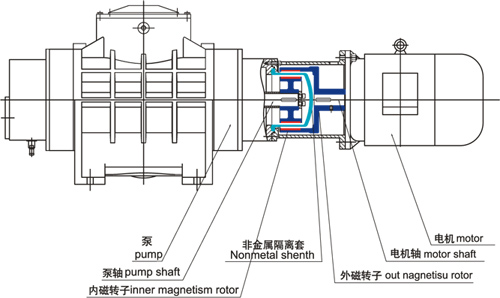

Characteristic:

● Magnetic force transmission transfer moment, the dynamic seal of the main shaft that transfer twist moment is calm seal (no framework oil seal and mechanical seal), it is achieved that there is no leak when the dynamical is being transferred.

● No machine contacting and Rubbing noise, avoid the high frequency vibration when dynamical is being transferred, stable operation.

● Possess overload self-protective function.

● No impact when start compare to Rigid coupling, Install \ dismantle to unload, test and maintain expediently.

● Sheath for insulation and Calm seal replaced moving seal. Vacuum and lubricant leak is avoided completely because of abrasion of the shaft moving seal.

● Do not need lubricate, no medium and lubricant pollutions, Purify the environment

The Sealing performance is foreign to the shaft speed.

Installation dimension and performance of the series pump is the same with the general roots pump.

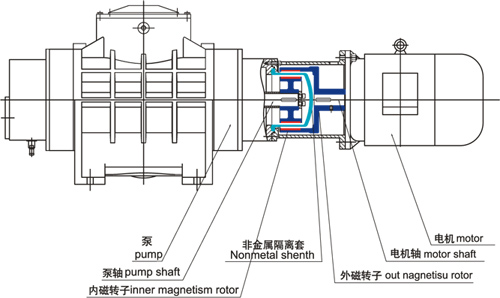

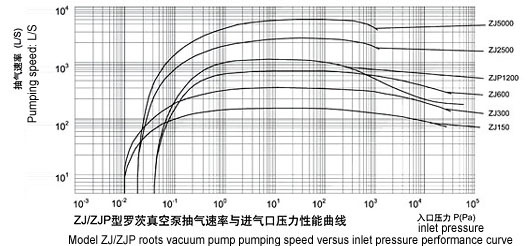

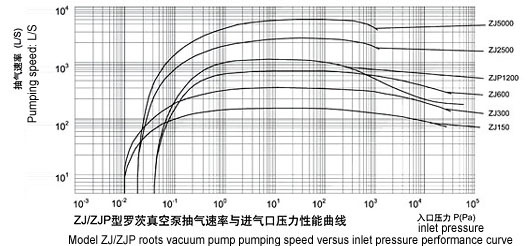

ZJ、ZJP型泵主要性能參數表

注:表中極限壓力是指用麥式真空計測得。

注:ZJP系列指帶溢流閥結構。

注:ZJC、ZJPC磁力驅動羅茨真空泵性能參數分別與ZJ、ZJP型泵相同。

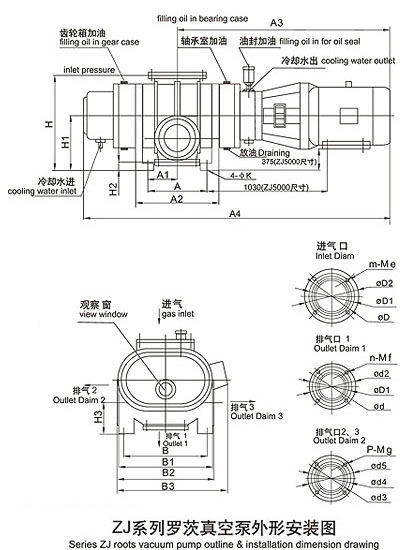

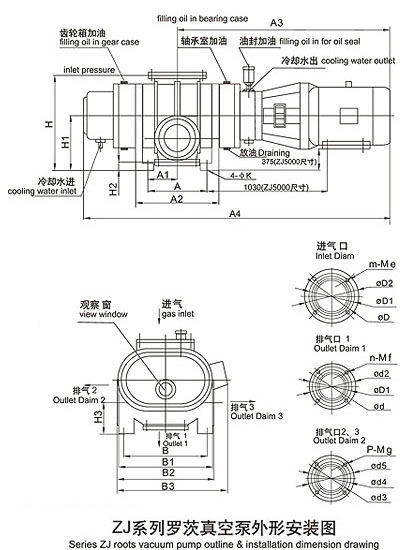

外形安裝圖:

| 型號 | 極限壓力帕(Pa) |

抽氣速率 升/秒(L/S) |

最大允許壓差 (HPa) |

進排氣口徑(mm) |

配用功率 kw |

零流量最大 壓縮比 |

重量 (Kg) |

||

|

配用雙級油封 機械真空泵 |

配用單級油封 機械真空泵 |

進氣 | 排氣 | ||||||

| ZJP-70 | ≤2x10-2 | ≤1x10-1 | 70 | 100 | 80 | 50 | 1.5 | ≥35 | 100 |

| ZJP-150 | 150 | 80 | 100 | 100 | 2.2/3 | ≥40 | 220 | ||

| ZJP-300 | 300 | 80 | 150 | 150 | 4 | ≥40 | 300 | ||

| ZJP-600 | 600 | 50 | 200 | 200 | 5.5/7.5 | ≥45 | 575 | ||

| ZJP-1200 | 1200 | 50 | 250 | 200 | 11/15 | ≥50 | 860 | ||

| ZJP-2500 | 2500 | 30 | 320 | 250 | 18.5/22 | ≥50 | 1480 | ||

| ZJ-30 | 30 | 100 | 50 | 40 | 0.75 | ≥30 | 55 | ||

| ZJ-70 | 70 | 100 | 80 | 50 | 1.5 | ≥35 | 90 | ||

| ZJ-150 | 150 | 80 | 100 | 100 | 2.2/3 | ≥40 | 210 | ||

| ZJ-300 | 300 | 80 | 150 | 150 | 4 | ≥40 | 285 | ||

| ZJ-600 | 600 | 50 | 200 | 200 | 5.5/7.5 | ≥45 | 550 | ||

| ZJ-2500 | 2500 | 30 | 320 | 250 | 18.5/22 | ≥50 | 1480 | ||

| ZJ-5000 | 5000 | 30 | 400 | 320 | 37/45 | ≥55 | 3400 | ||

注:ZJP系列指帶溢流閥結構。

注:ZJC、ZJPC磁力驅動羅茨真空泵性能參數分別與ZJ、ZJP型泵相同。

性(xing)能曲(qu)線(xian)圖:

外形安裝圖:

| Model | A | A1 | A2 | A3 | A4 | B | B1 | B2 | B3 | H | H1 | H2 | H3 | D | D1 | D2 | d | d1 | d2 | d3 | d4 | d5 | m | n | p | e | f | g | k |

| ZJ70 | 330 | 120 | 370 | 584 | 829 | 219 | 247 | 324 | 226 | 122 | 18 | 90 | 125 | 145 | 50 | 90 | 110 | 4 | 4 | 8 | 8 | 18 | |||||||

| ZJ150B | 115 | 57.5 | 154 | 675 | 950 | 320 | 360 | 380 | 448 | 345 | 205 | 35 | 95 | 100 | 145 | 170 | 100 | 145 | 170 | 80 | 125 | 145 | 4 | 4 | 4 | 10 | 10 | 10 | 18 |

| ZJ150BJ | 440 | 118 | 480 | 675 | 950 | 320 | 370 | 380 | 448 | 380 | 240 | 70 | 130 | 100 | 145 | 170 | 100 | 145 | 170 | 80 | 125 | 145 | 4 | 4 | 4 | 10 | 10 | 10 | 18 |

| ZJ300B | 225 | 112.5 | 314 | 775 | 1125 | 320 | 360 | 370 | 452 | 345 | 205 | 35 | 120 | 150 | 195 | 220 | 150 | 195 | 220 | 100 | 145 | 170 | 8 | 8 | 8 | 10 | 10 | 8 | 18 |

| ZJ300BJ | 600 | 197 | 640 | 775 | 1125 | 320 | 360 | 370 | 452 | 380 | 240 | 70 | 155 | 150 | 195 | 220 | 150 | 195 | 220 |

100 |

145 | 170 | 8 | 8 | 8 | 10 | 10 | 8 | 18 |

| ZJ600B | 170 | 85 | 250 | 896 | 1270 | 500 | 550 | 570 | 610 | 530 | 320 | 40 | 170 | 200 | 250 | 285 | 160 | 200 | 225 | 160 | 200 | 225 | 8 | 8 | 8 | 10 | 10 | 10 | 18 |

| ZJ5000 | 655 | 327.5 | 880 | 1915 | 2720 | 1020 | 1120 | 1150 | 1200 | 1050 | 600 | 40 | 250 | 400 | 480 | 510 | 320 | 395 | 425 | 320 | 395 | 425 | 16 | 12 | 12 | 12 | 12 | 12 | 32 |